We would like to invite all interested inhabitants for a meeting devoted to construction of the modern installation for thermal processing of waste. The meeting will take place in As restaurant at 4 Fabryczna street in Inowrocław. The investors will present the investment project, and then they will answer the questions of the inhabitants.

Ino.Online asked us a series of questions about the project to build a thermal waste treatment facility in Inowrocław. Frank Paasche, Board Member of EEW Energy From Waste Sp. z o.o. answered all of them. We invite you to read: Spalarnia odpadów. Inwestor odpowiada na nasze pytania.

Will the installation be safe, what does the investment mean for the future of Ciech Soda Polska, what will be used as fuel and whether the fears concerning the new investment are justified - you can read all about it in the interview by Gazeta Pomorska with Tomasz Molenda, acting president of Ciech Soda Polska. More

We have launched the "News" section on our website. There, we will keep you informed about the progress of the project and publish all the important information concerning the investment. We encourage you to visit the site regularly.

Can thermal waste treatment plants be located in proximity to built-up areas?

This is the case in many cities, the most famous of which are cities such as Vienna and Copenhagen. In Europe, more than 400 thermal waste transformation plants based on the technology to be used in Inowrocław operate successfully. This, combined with the best available solutions and rigorous procedures, means that the installations are not only safe for people. It also contributes to reducing waste landfill which methane emissions are up to 25 times more climate-damaging than CO2.

Will residents be informed about the investment?

Yes, and in different ways. The most reliable source of up-to-date information will be the website, which we will update. We are also planning an information point in the City, as well as other information and education activities. We believe that reliable communication is essential to build public acceptance, without which the project will not be possible.

How are odour nuisances from such installations eliminated?

In several ways. Odour nuisance is strictly controlled at the waste preparation, transport and thermal treatment stages. The main stream is the calorific (dry) fraction of mixed waste, coming from the mechanical-biological processing facility, previously stripped of the fine fraction, representing the greatest risk of odour nuisance. Thus prepared waste will be transported in specially adapted, tightly covered vehicles, away from residential areas. The bunker into which the waste is unloaded will be equipped with a ventilation system to ensure adequate negative pressure throughout the combustion process. This means that even when unloading the waste, no unpleasant odours will escape. What is more, the air required for the incineration process will be taken from the bunker and will be completely odour-neutral during the process.

The plant in Inowrocław will be used to generate energy. What standards apply to thermal treatment of waste processes and how do they compare to coal combustion standards?

The standards for thermal treatment of waste are much stricter than for coal. The installation will meet EU and Polish environmental standards for air emissions. It is worth knowing that emission standards are precisely defined in the Regulation of the Minister of Climate on emission standards for certain types of installations, fuel combustion sources and waste incineration or co-incineration devices of 24 September 2020 and additionally in the so-called BAT Conclusions for waste incineration. The installation will be safe for residents and the environment.

Will the installation emit noise?

Like any such installation, it will be a source of noise. However, the operation of the installation cannot and will not lead to exceeding the environmental protection standards in terms of noise emission. The location of the installation in a strictly industrial area means that the emitted noise will not affect the comfort of life of Inowrocław residents.

How is groundwater protected?

Building this type of installation involves eliminating many risk factors. Groundwater protection is no different. The bunker that will hold the waste will be sealed and not connected to the sewage system. If some waste deliveries are excessively wet then the excess water will be absorbed by other wastes that are mixed together inside the bunker.

What type of waste will go to the Inowrocław facility?

The fuel for the installation will be predominantly treated municipal waste, i.e. the high calorific fraction of mixed municipal waste (pre-RDF). This waste is the fraction that is not suitable for material recycling and landfilling is legally not permissable. It is typically a mixture of multi-material packaging (e.g. juice, milk products), soiled soft packaging plastics, soiled hard plastics (e.g. toy parts), sponges, textiles, shoes, soiled paper and cardboard, etc. This will be complemented by a small stream of selected industrial waste. Radioactive, medical or other waste that is considered to be harzardous will not be processed.

Will waste be stored on site?

The waste will be delivered on a daily basis and will go directly into a sealed bunker from where it will be continuously drawn into the process. The fuel stored inside the bunker will be sufficient for 3-4 days of operation. However, during short term downtimes provision is made for a temporarily storage of waste on site. The waste will be stored in bails in a warehouse with a sealed floor. The waste dosn't emit any odour since it is wrapped in plastic foil.

Why will a thermal waste conversion plant be built in Inowrocław?

Thermal waste conversion plants are only justified where there is a demand for heat. The new installation is an element of the modernisation of CIECH Soda Polska's plant in Inowrocław, which consists in reducing coal consumption in the energy production process and switching off part of the installation to produce energy from coal. Obtaining energy from the thermal waste processing installation is more environmentally friendly, and what is equally important, will significantly affect the competitiveness of the plant. It will contribute to reduction of energy production costs, which have risen sharply in recent years (raw materials, CO2 emission allowances).

Who will finance the construction of the installation?

The investment will be financed entirely by EEW Group. The company is financially sound due to their strong competitive position and proven business model. The project will be realized without any support from local government or EU funds.

What about the spa character of Inowrocław?

It will continue to be maintained. Inowrocław is proof that it is possible to perfectly combine two functions of a city, an important industrial centre and a health resort at the same time. There are examples of the functioning side by side of health resorts and facilities such as the one being prepared in Inowrocław, e.g. in Germany, where EEW has built several facilities in the vicinity of health resorts or particularly valuable natural areas.

Do thermal waste treatment installations work in Europe?

Yes, thermal waste conversion installation have been operating in western European countries for many years. They are often built in the centres of densely populated cities (Vienna, Paris, Berlin) and at the same time provide residents with heat and electricity. The use of state-of-the-art technologies makes the installations fully safe and unobtrusive for residents and the natural environment.

Thermal waste treatment installations in Europe.

There are currently nine thermal waste treatment plants operating in Poland (e.g. in Bydgoszcz, Białystok, Kraków, Poznań, Warsaw and Rzeszów). They produce electricity and heat, which is transferred to destrict heating networks. Two further installations are being built in Gdańsk and Olsztyn (both investments are co-financed with EU funds).

The amount of waste generated in Poland is increasing. According to EU requirements, by 2035 Poland must reduce the percentage of landfilled waste increase recycling rate of municipal waste. The annual capacity of thermal waste treatment plants should be increased by about 3 million tons.

The salt industry has shaped the city for nearly 150 years. The first soda factory was established in 1879 in the Mątwy district. The planned installation will be built in the industrial area belonging to Ciech Soda Polska S.A. The new installation will become part of the industrial complex that has existed for over 100 years.

The installation will be characterized by high energy recovery, reliability and will be equipped with a multi-stage exhaust gas cleaning system, the latest generation, with an SCR catalyst. SCR or Selective catalytic reduction technology converts nitrogen oxides (NOx) into nitrogen and water vapour and thus into components that are not harmful to the environment and are already naturally present in the atmosphere.

Using waste to generate energy reduces the burning of fossil fuels such as coal and gas reduces CO2 emissions. The standards for thermal waste conversion are much stricter than for burning coal.

A large part of the process waste generated in the thermal treatment of waste can be usefully managed and used in a completely safe manner. Slags are used, for example, in road construction to replace natural aggregates. Metals can be easily recovered from process waste.

The installation will be built in Inowrocław, on an industrial area belonging to Ciech Soda Polska S.A. The installation will occupy a plot of about 3 hectares, which is located within the Ciech Soda Polska plant, the recipient of the steam.

The new installation will become part of an industrial complex that has existed for over 100 years. Thanks to visualisations it is possible to see how the installation will look after it is put into operation.

The plant is designed for continuous operation, all year round. Service and maintenance breaks, including shutdown and restart, typically last up to 3 weeks per year. During this time the combustion process does not take place.

Fuel will be delivered by lorry. The waste delivery trucks will travel on the bypass and the proposed route avoids residential areas. It is estimated that there will be a slight increase in HGV traffic compared to the current road load. Approximately 80 vehicles per day delivering waste fuel and remove combustion residues. Conceptual work is underway to further reduce the impact of transport in the surrounding area.

Trucks will enter the site through the main gate located to the east. The trucks will pass a weighbridge. After a cargo check trucks will approach the bunker gate. The gate will open and unloading process begins. The bunker will be under negative pressure, which effectively prevents odours from escaping. Air from the bunker will be extracted and used for the combustion process, thus not escaping to the outside. During maintenance breaks when combustion is not taking place, the air from the bunker will be additionally filtered. The waste in the bunker will be aerated and homogenised before being fed into the hopper using a gripper on the crane.

From the hopper, the waste will go directly to a moving grate, on which it will move downwards while processing under optimal aeration conditions. The combustion temperature will be at least 850 degrees Celsius. At these high temperatures, the waste will combust without any additional fuel. Fuel oil is only used for start-up, to bring the furnace up to temperature and for shutting down the operation. In the combustion process, the waste is the only fuel. At high temperatures inside the boiler, harmful substances are broken down.

The complex, multi-stage flue gas cleaning system with catalytic reduction of nitrogen oxides is an important part of the process and guarantees a high efficiency while meeting the stringent environmental standards set out in the BAT conclusions and Regulation of the Minister of Climate on emission standards for certain types of installations, fuel combustion sources and waste incineration or co-incineration devices of 24 September 2020. Sensors mounted on the chimney will continuously monitor emissions 24 hours a day.

The thermal treatment of waste naturally generates combustion products. These include slag and dust from flue gas cleaning. The slag will be subjected to a valorisation process, i.e. mechanical processing with recovery of ferrous and non-ferrous metals in specially prepared plants. It can then be used as an admixture to construction aggregate used in road construction. As for dust, it is currently planned to store it in specially prepared empty pits in mines in Germany or other regions, in line with EEW's long-standing practice.

Environmental protection and saving resources

INOWROCŁAW NOWA ENERGIA is also an investment in environmental protection and saving resources. The plant will supply around 750 GWh/a of energy in the form of process steam. This is more than one third of the demand for heat energy of Ciech Soda Polska in Inowrocław. Municipal waste as a source of energy is an environmentally friendly and at the same time economical alternative, as it consists of around 50% of biogenic materials and is therefore combusted in a carbon-neutral manner. The plant will also bring significant benefits in terms of waste management. The waste currently generated by households is often collected selectively and sent to sorting plants and mechanical-biological processing plants, where, among other things, secondary raw materials are separated. However, there are wastes which cannot be recycled, e.g. due to their multi-material structure, degree of soiling or dampness. According to current legislation, they also cannot be landfilled because their calorific value exceeds 6 MJ/kg. The economically rational and environmentally safe way to manage these waste fractions is to incinerate them in a strictly controlled process. The plant will be able to generate energy by processing up to 310,000 tonnes of such waste per year. This will include regional waste as well as waste from other provinces, where there is still a deficit in environmental friendly thermal processing capacity.

It is also worth emphasizing the fact that the project under preparation will also contribute to the reduction of methane emissions. Methane, next to carbon dioxide, is the main greenhouse gas. It has a higher heat-trapping potential than CO2, but it decomposes faster in the atmosphere. This means that reducing methane emissions is important to stop global warming.

A project for the economic future of Inowrocław.

Inowrocław is situated in the Kujawsko-Pomorskie Voivodship, approximately 40 km south-east of Bydgoszcz. The city combines two important functions: spa and industry. The development of both is closely related to salt mining. The salt industry has shaped the city for over 150 years. The first soda factory was established in 1879 in the Mątwy district.

Today Inowrocław is one of the most important centres of the chemical industry in Poland. The Ciech Soda Polska plants are an important link in the economy of the commune and the district. They provide jobs for the local community and are a source of stable taxes, which go to the city budget. Ciech Soda Polska is the second largest manufacturer of soda ash and baking soda and the third largest supplier of evaporated salt in Europe. Such a scale of production requires a huge amount of energy. Currently the plant obtains it from coal, but the company is gradually moving away from the use of fossil fuels in production.

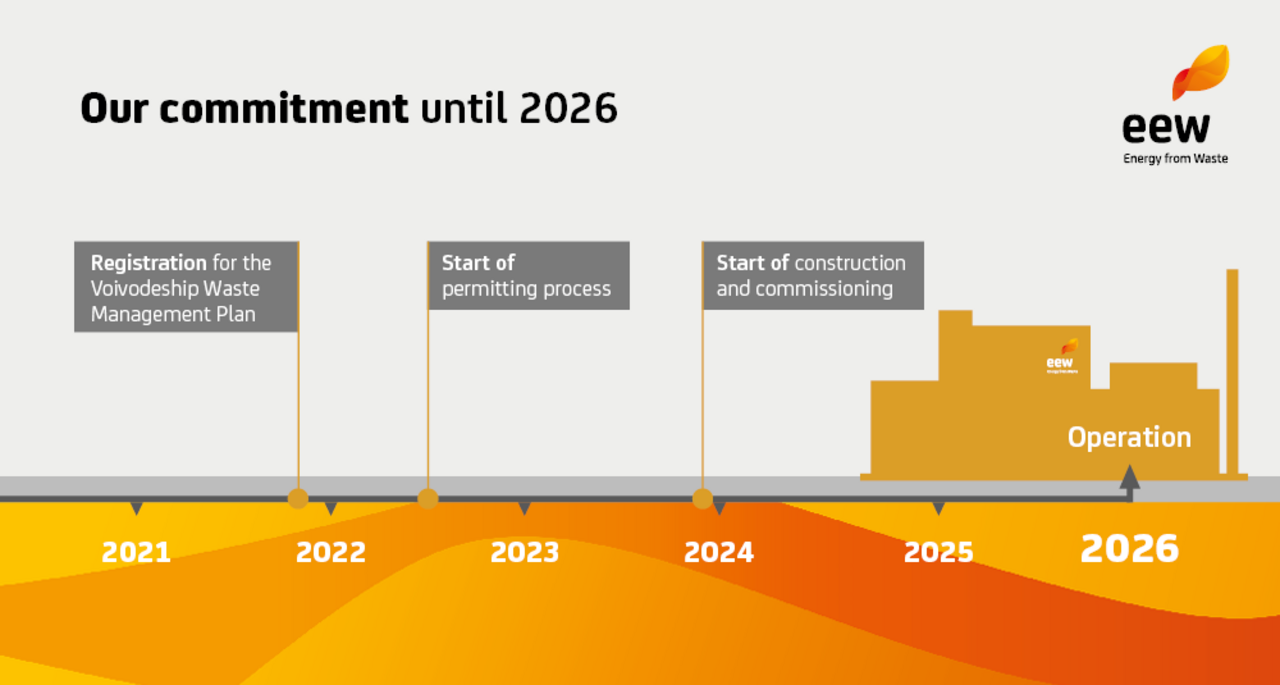

INOWROCŁAW NOWA ENERGIA – is an investment which consists in the construction of a municipal waste thermal treatment facility with auxiliary infrastructure. It will be located within the complex of Ciech Soda Polska in Inowrocław. After its completion it will cover one third of the energy demand of the Ciech´s industrial complex. The project will be carried out the German EEW Energy from Waste Group. At a time of rising energy prices and CO2 certificates the plant will ensure a stable future for the Inowrocław plant and hundreds of companies associated with its operation. Construction is planned to begin in 2024 and will last less than three years until the plant is operational in 2026.

Project partners

EEW Energy from Waste has been designing, building, expanding, modernising and managing thermal waste treatment plants for over fifty years. All EEW plants meet stringent EU standards. The company operates a total of seventeen thermal waste treatment plants which annually convert more than 5 million tonnes of waste into energy to supply towns and major industrial centres. Fifteen plants are located in Germany, one in Luxembourg and another one in the Netherlands. The company is building eight new facilities.

EEW's experience, with completed plants that have been operating safely for many years, not only in cities but also in the vicinity of environmentally valuable areas, enables the realisation of projects characterised by environmentally friendly architecture and the most efficient combustion and flue gas cleaning technology. EEW plants are constantly modernised and equipped with the best available technology. All EEW managed plants meet BAT (best available technique) criteria. EEW is also carrying out advanced research into the development of thermal waste conversion technologies, such as CO2 capture systems.

Every day, 1,250 EEW's employees ensure that all of its plants operate in a stable manner. The company's activities have a positive impact on the local environment – EEW uses a number of local companies to procure a range of maintenance services for its plants.

EEW Energy from Waste Polska Sp. z o.o. is a 100% subsidiary of EEW Energy from Waste GmbH.

FBSerwis belongs to the Budimex Group. It is one of the largest companies on the Polish waste management market, currently collecting waste from about half a million residents of cities and communes throughout Poland. The company also provides maintenance services for buildings and industrial facilities (e.g. PGE Narodowy, Port of Gdańsk), performs summer and winter maintenance of over 1,800 km of national roads and motorways as well as provides services for street lighting modernisation.

FBSerwis Group includes 4 companies operating municipal waste treatment plants, including mechanical-biological waste treatment facilities, alternative fuel production facilities and landfill sites. Modern technologies used in the Group's facilities ensure the safety of all processes, minimise the impact of waste processing on the environment, and enable effective recovery of materials so that they can be reused. These facilities operate based on the Integrated Permit decisions issued by province marshals and are safe for the environment.

Budimex Group, to which FBSerwis belongs, is the largest construction group in Poland. It has experience not only in the execution of the most important infrastructure investments in the country, but also in the waste management sector. Budimex was the leader of a consortium that built a thermal waste treatment plant in Białystok. In Inowrocław, Budimex has executed a project for redevelopment of the area around the PKP railway station.

Download Imagebroschüre

Download Facts and figures brochure

Download Sustainability Report 2020